BSPP Female O-Ring Swivel – Global Spiral

Price range: $23.360 through $442.810 ex GST

Description

BSPP Female O-Ring Swivel – Global Spiral

Gates BSPP Female O-Ring Swivel – Global Spiral hose couplings are part of a two-piece coupling specifically designed for use on Gates’ range of hydraulic hoses.

Global Spiral Couplings – Suits EFG3K, EFG4K, EFG5K, EFG6K

D3 – Fittings for Spiral Hose – Product Download

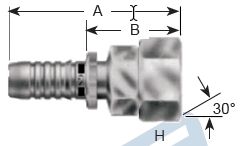

| MJ Hydraulic Part Number | Gates Desc. | Hose ID | Thread size | A | B | H | |

| inch | mm | mm | mm | mm | |||

| GSBF-06-06 | 6GS-6FBSPORX | 3/8 | 9.5 | G 3/8” – 19 BSP | 59.4 | 23.5 | 22.0 |

| GSBF-08-06 | 6GS-8FBSPORX | 3/8 | 9.5 | G 1/2” – 14 BSP | 60.2 | 24.4 | 27.0 |

| GSBF-08-08 | 8GS-8FBSPORX | 1/2 | 12.7 | G 1/2” – 14 BSP | 61.0 | 23.5 | 27.0 |

| GSBF-10-08¥ | 8GS-10FBSPORX | 1/2 | 12.7 | G 5/8” – 14 BSP | 62.0 | 29.2 | 30.0 |

| GSBF-10-10 | 10GS-10FBSPORX | 5/8 | 15.8 | G 5/8” – 14 BSP | 80.5 | 30.2 | 30.0 |

| GSBF-12-10¥ | 10GS-12FBSPORX | 5/8 | 15.8 | G 3/4” – 14 BSP | 82.3 | 32.0 | 32.0 |

| GSBF-12-12 | 12GS-12FBSPORX | 3/4 | 19.1 | G 3/4” – 14 BSP | 85.0 | 34.0 | 32.0 |

| GSBF-16-16 | 16GS-16FBSPORX | 1 | 25.4 | G 1” – 11 BSP | 95.0 | 38.6 | 41.0 |

| GSBF-20-20 | 20GS-20FBSPORX | 1-1/4 | 31.7 | G 1.1/4” – 11 BSP | 116.5 | 45.4 | 50.0 |

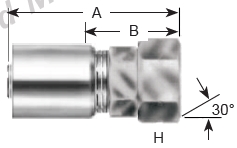

| MJ Hydraulic Part Number | Gates Desc. | Hose ID | Thread size | A | B | H | |

| inch | mm | mm | mm | mm | |||

| GSPBF-24-24 | 24GSP-24FBSPORX | 1 1/2 | 38.1 | G 1 1/2-11 BSP | 125.0 | 51.3 | 55.0 |

| GSPBF-32-32 | 24GSP-32FBSPORX | 2 | 50.8 | G 2-11 BSP | 153.0 | 61.0 | 70.0 |

| MJ Hydraulic Part Number | Gates Desc. | Hose ID | Thread size | A | B | H | |

| inch | mm | mm | mm | mm | |||

| GSMBF-24-24 | 24GSM-24FBSPORX | 1 1/2 | 38.1 | G 1 1/2-11 BSP | 154.0 | 59.0 | 55.0 |

| GSMBF-32-32 | 24GSM-32FBSPORX | 2 | 50.8 | G 2-11 BSP | 184.0 | 70.0 | 70.0 |

¥ Coupling pricing & availability on request.

Gates eCrimp provides the most up-to-date crimp specifications for all Gates hose and fitting combinations.¥ Coupling pricing & availability on request.

The Gates GlobalSpiral Coupling is a no-skive, easy to use coupling which provides a high quality performance and can be used for extremely high-pressure and high-impulse hydraulic applications. The no-skive ferrule abolishes the need for skiving equipment while also reducing labour and assembly time as well reducing odours, contamination from dust and assembly errors.

FULL-TORQUE NUT™ DESIGN – One of the most common causes of hydraulic leaks is a cracked coupling nut or seat due to over-torquing by a strong-armed worker. Gates has engineered a solution – Full-Torque Nut™ technology now available on Gates MegaCrimp and GlobalSpiral® couplings.

Additional information

| Model | GSBF-06-06, GSBF-08-06, GSBF-08-08, GSBF-10-08, GSBF-10-10, GSBF-12-10, GSBF-12-12, GSBF-16-16, GSBF-20-20, GSPBF-24-24, GSPBF-32-32, GSMBF-24-24, GSMBF-32-32 |

|---|