Double Acting – Industrial Cylinders

Description

Double Acting – Industrial Cylinders

Force: 5-25 t

Stroke: 30-260 mm

Max Working Pressure: 700 Bar

Features

All COD cylinders have a threaded body, rod, and base. This feature makes them extremely versatile. A complete range of accessories for working with various applications are available. The guide and end of stroke nut are provided with a wiper to prevent the entrance of dirt and to improve the working life of the cylinder.

Operational Areas

These cylinders are used in industrial applications where a large number of cycles are required. They are used in blocking operations, in laboratories, and for tests that need pushing and pulling forces. The nitride anti-corrosive treatment makes them suitable for work in harsh environments and in the open air.

Accessories

- ZAE Clevis eyes to be mounted on the rod or at the bottom.

- ZAF Flange to be mounted on the machined ends of the body.

- ZAP Plate to be mounted on the machined ends of the bod as an alternative to the flange.

- ZAA Nut to block either the flange or the plate.

Given their unusual mounting, these cylinders are supplied without the female K73F half-couplers, which can be ordered separately if required.

Selection Chart

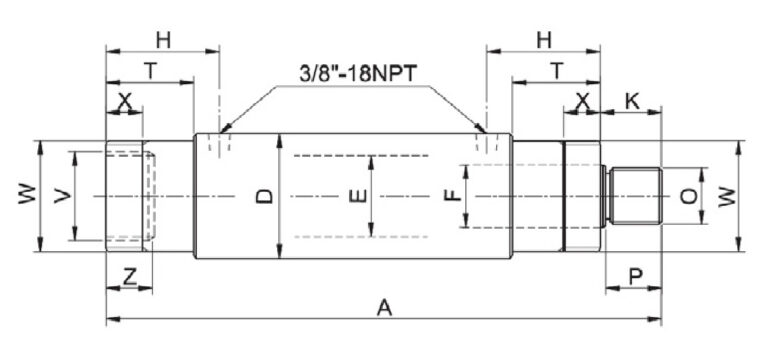

| PUSHING FORCE | PULLING FORCE | STROKE | PUSHING EFFECTIVE AREA | PULLING EFFECTIVE AREA | PUSHING OIL VOLUME | PULLING OIL VOLUME | MODEL | CLOSED HEIGHT | Ø EXTERNAL | Ø PISTON | Ø ROD | COUPLER HEIGHT | ROD PROJECTION | ROD THREAD | ROD THREAD LENGHT | COLLAR LENGHT | INTERNAL BASE THREAD | INTERNAL BASE THREAD DEPTH | COLLAR THREAD | COLLAR THREAD LENGHT | WEIGHT | * Nominal value, for precise capacity see kN |

| t*kN | t*kN | mm | cm² | cm² | cm3 | cm3 | Amm | Dmm | Emm | Fmm | Hmm | Kmm | Omm | Pmm | Tmm | Vmm | Zmm | Wmm | Xmm | kg | ||

|

5 |

3 |

30 | 7.1 | 3.9 | 21 | 12 | COD5N30 | 185 | 50 | 30 | 20 | 45 | 22 |

M18 |

19 | 26 |

M35 |

13 |

M42 |

9 | 2.1 | |

| 80 | 57 | 31 | COD5N80 | 235 | 2.8 | |||||||||||||||||

| 160 | 113 | 63 | COD5N160 | 315 | 3.8 | |||||||||||||||||

|

10 |

6 |

30 | 13.9 | 8.9 | 42 | 27 | COD10N30 | 204 | 63 | 42 | 25 | 54 | 23 |

M22 |

20 | 35 |

M42 |

15 |

M56 |

15 | 3.6 | |

| 80 | 111 | 72 | COD10N80 | 254 | 4.5 | |||||||||||||||||

| 160 | 222 | 143 | COD10N160 | 334 | 5.8 | |||||||||||||||||

| 260 | 360 | 233 | COD10N260 | 434 | 7.3 | |||||||||||||||||

|

15 |

8 |

160 | 19.6 | 11.6 | 314 | 185 | COD15N160 | 376 | 80 | 50 | 32 | 71 | 31 |

M30 |

28 | 52 |

M56 |

27 |

M70 |

16 | 10.8 | |

| 260 | 511 | 301 | COD15N260 | 476 | 13.9 | |||||||||||||||||

|

25 |

12 |

160 | 33.1 | 17.3 | 531 | 276 | COD25N160 | 412 | 92 | 65 | 45 | 84 | 41 |

M42 |

38 | 65 |

M70 |

30 |

M85 |

20 | 15.5 | |

| 260 | 863 | 449 | COD25N260 | 512 | 19.4 |

Contact us for further technical information.

Europress, founded in 1919, is a worldwide leader, manufacturer and marketer of high-pressure hydraulic equipment. We continuously improve our services to offer you better options. Our effort in following the most advanced technology innovations in terms of quality, safety, and reliability are certified since 1996, year in which we have been awarded with the ISO 9001 Quality System Certification , and more recently in 2008 with the ISO 14001 Quality System Certification.

Additional information

| Model | COD5N30, COD5N80, COD5N160, COD10N30, COD10N80, COD10N160, COD10N260, COD15N160, COD15N260, COD25N160, COD25N260 |

|---|